Roll welding machine is a machine used for roll welding. Roll welding, also known as circular seam welding, is a method of using a pair of roller electrodes instead of cylindrical electrodes for spot welding.

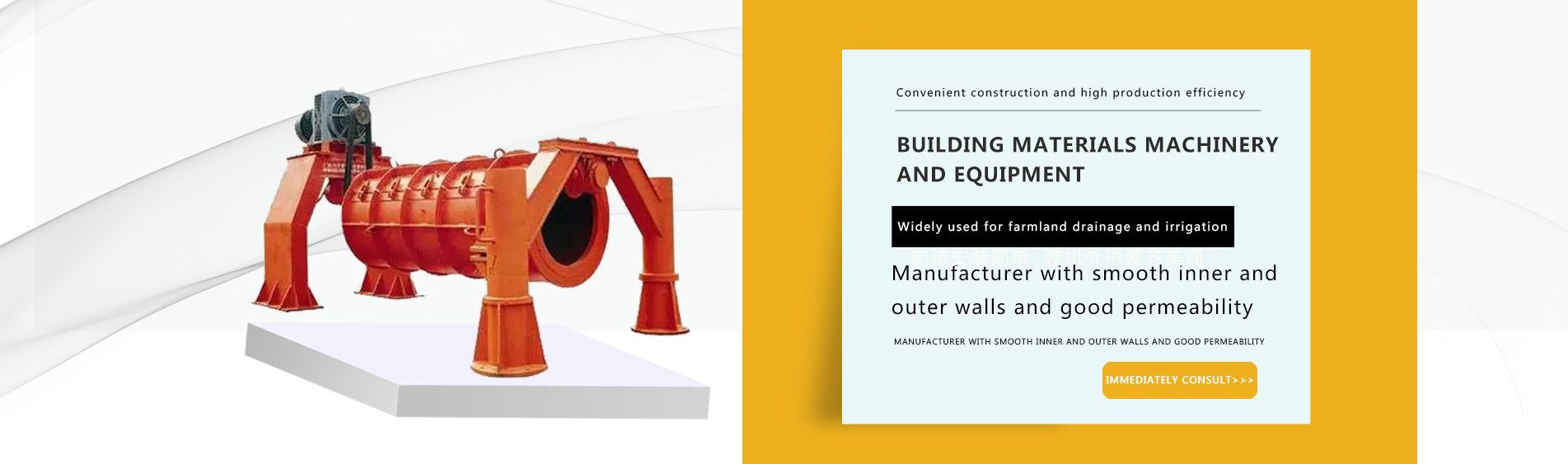

Product Introduction:

Roll welding machine is a machine used for roll welding. Roll welding, also known as circular seam welding, is a method of using a pair of roller electrodes instead of cylindrical electrodes for spot welding. The welded workpiece moves between the roller plates, creating a sealed weld seam with overlapping fusion nuclei to weld the workpiece together. Generally, AC pulse current or amplitude modulation current can be used, and three-phase (single phase) rectification, intermediate frequency, and high-frequency DC current can also be used. Roll welding is widely used in thin plate welding of sealed containers in oil drums, cans, radiator, aircraft and automobile fuel tanks, rockets and missiles. The general welding thickness is within 3mm of the single plate.