The cement well tube centrifuge is one of the main equipment for producing reinforced concrete well tubes. The unit adopts a box structure, consisting of supporting rollers and bearing seats. The supporting rollers are processed from cast steel parts, and are driven by a stepless speed control motor. The control device has a wide speed range, good bearing sealing, convenient maintenance, simple op

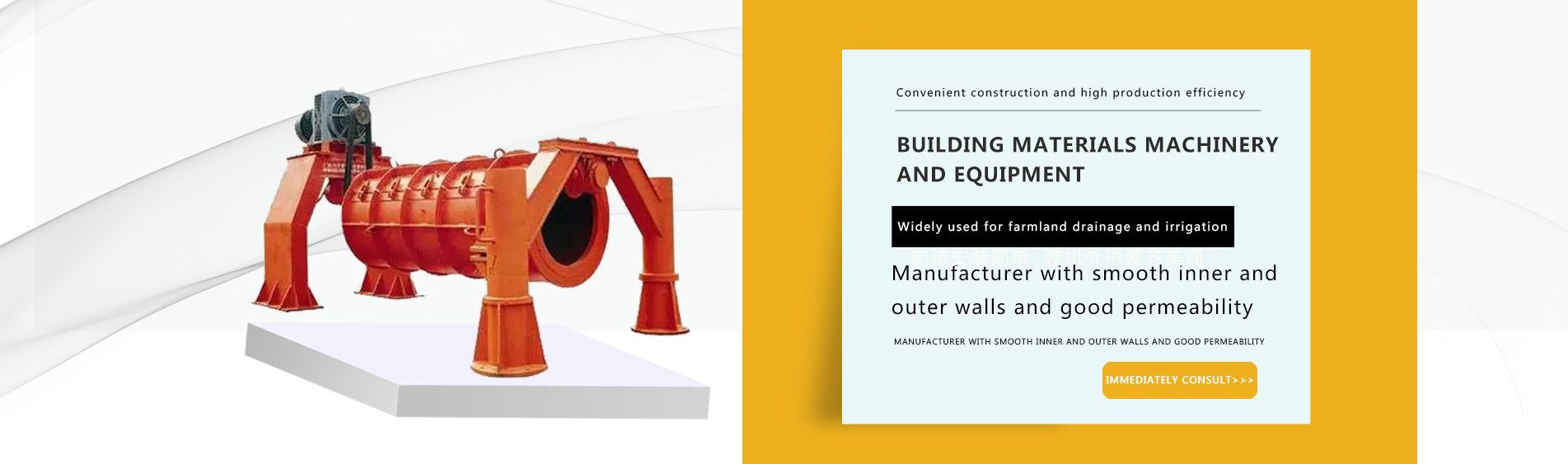

The cement well tube centrifuge is one of the main equipment for producing reinforced concrete well tubes. The unit adopts a box structure, consisting of supporting rollers and bearing seats. The supporting rollers are processed from cast steel parts, and are driven by a stepless speed control motor. The control device has a wide speed range, good bearing sealing, convenient maintenance, simple operation, and safety and reliability.

The centrifuge is composed of a base, supporting rollers, bearing seats, motors, control cabinets, and drive shafts, and the overall performance must meet the following requirements: